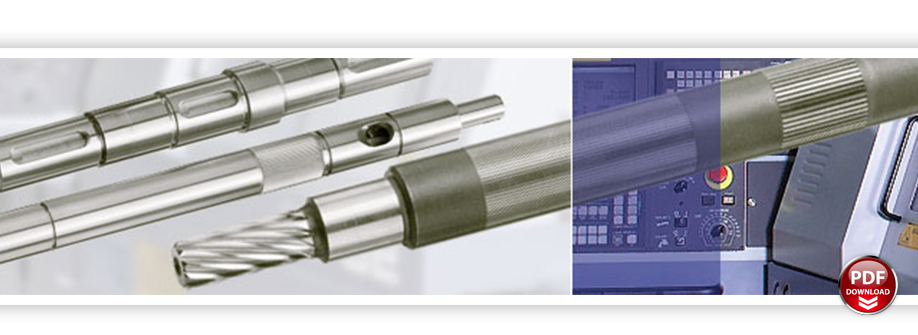

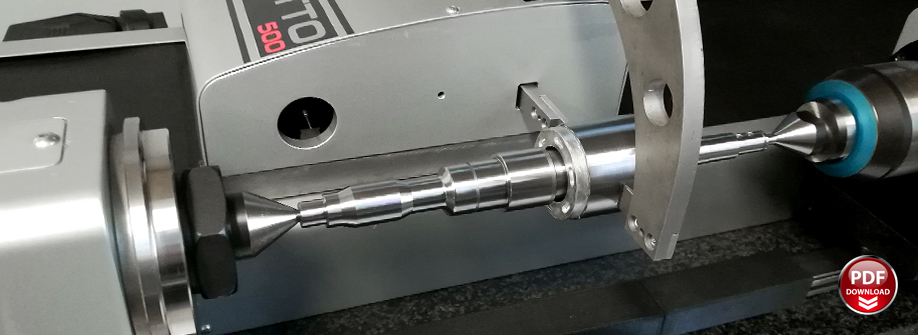

cptrade has always specialised in offering precision mechanical machining services, such as:

- rolling

- turning

- threading

- gear cutting

- grinding

- broaching

- milling

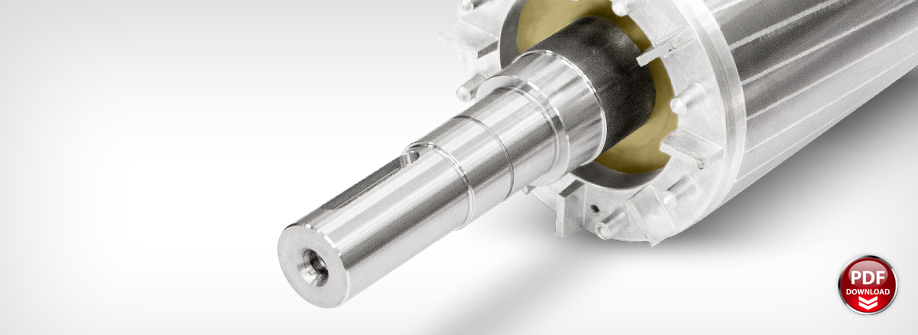

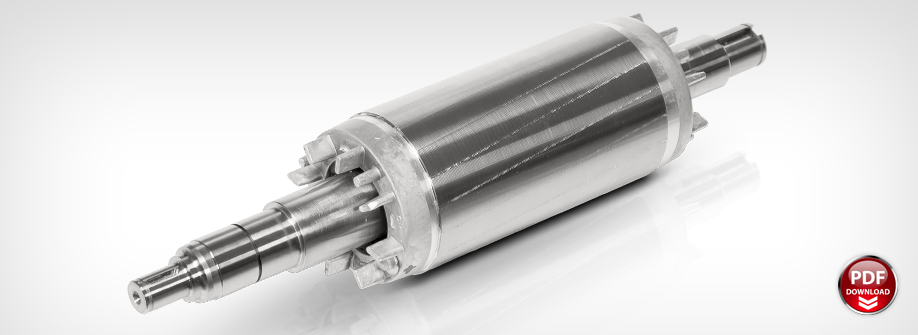

CPTRADE srl. produces components for electric motors.

For over 30 years our companies have been manufacturing electric motors, components and plastic accessories; with a long time of technological experience, innovations and safety of products has permitted us to obtain the QUALITY SYSTEM ISO9001.

We are looking through our history with determination to the global future for supplying the client with standard and customized solutions.

The most important point for our group is offering reliability & service:

WE ARE CUSTOMER ORIENTED

• From analysis of requirements to product design;

• From prototype to test of performance;

• From sales assistance to after-sale support;

• From project to supply of electric motor components on high efficiency;

• Norm: MEC – IEC – GOST.

NORM IEC 60034-30:2008

Download the IEC complete document.

- Enterprise system certification UNI EN ISO 9001:2015

- Enterprise system certification UNI EN ISO 9001:2015 - Enterprise system certification UL E535045 system designation CPT-UL1553

- Enterprise system certification UL E535045 system designation CPT-UL1553